Adapt to win

Project needs are constantly changing. Proggio is the project portfolio management solution that adapts to shifting needs and risks. It’s how you propel the future of your company forward.

Manage every phase of a project, even when there are 100s of them.

Proggio can handle all of your projects in one solution and makes it easy to see them in one view. Because success is complicated, we simplify so you can win.

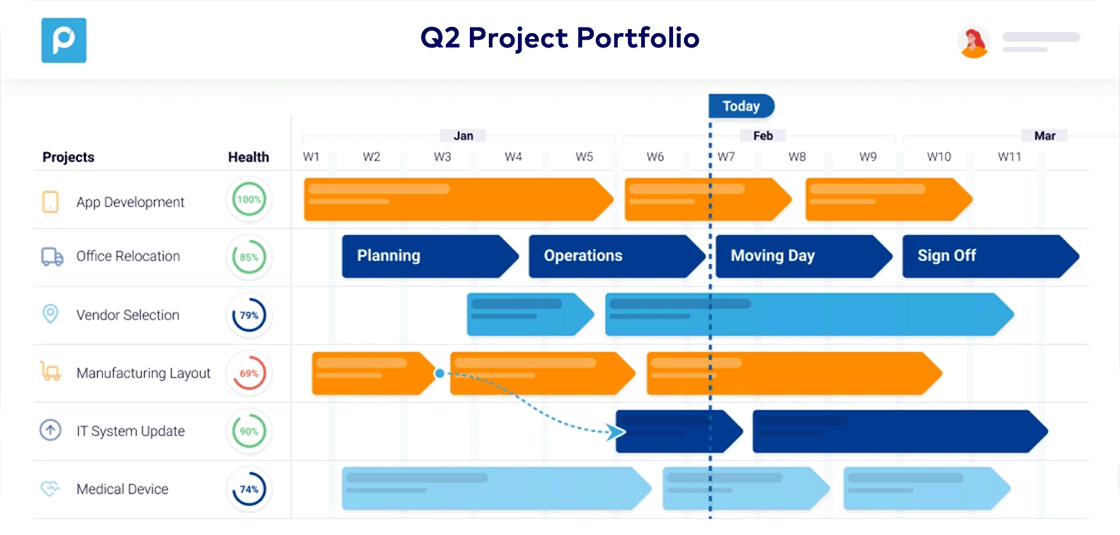

You can’t gauge success without calculating risk.

With Proggio, all of your project’s risks are automatically calculated, updated, and displayed in a single view — because your time should be spent handling risks, not being bogged down by them.

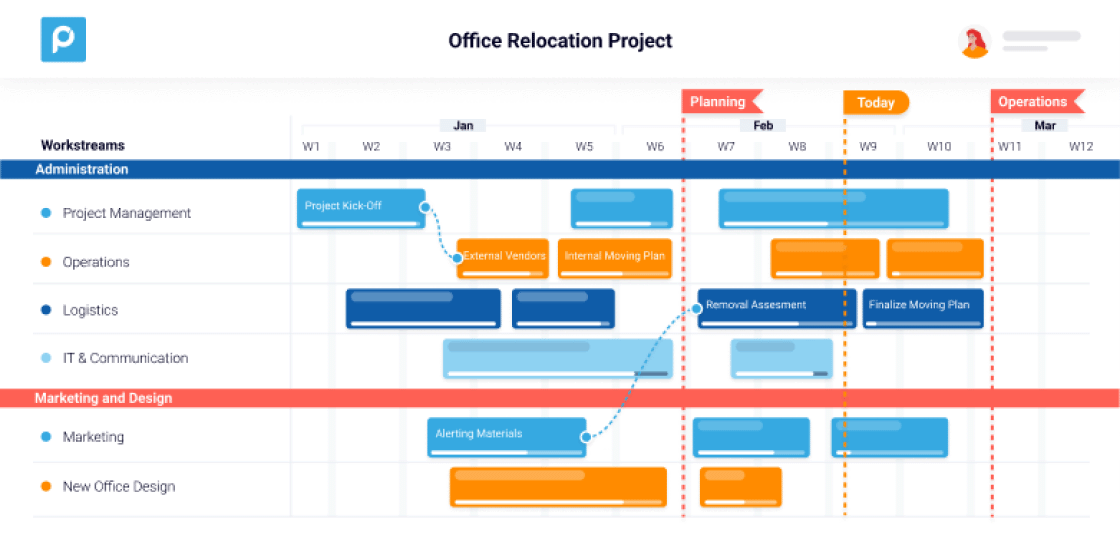

Introducing ProjectMap™.

It does what Gantt can’t.

A modern, cloud-based solution that leverages data to support management decision-making processes, Proggio delivers complete clarity and visibility in real time. Zoom in and out to go from a 30,000-foot high-level view down to a detailed what-if analysis, all without the limitations and inaccuracies of Gantt-based solutions.

- Manage your project pipeline

- Seamlessly run what-if analyses

- Execute with modern layered technology

Focus on the right projects. Invest in the right initiatives.

Our flexible project prioritization system makes it easy to pick projects that align with your organization’s business goals.

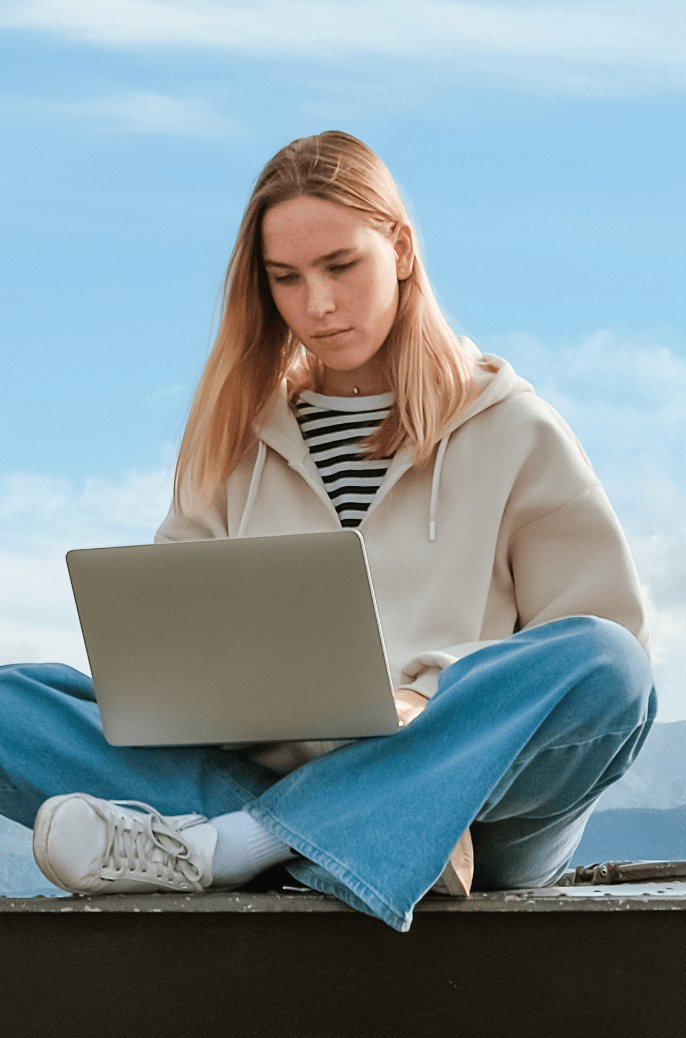

When everyone works better, your organization does better work.

Proggio makes it easy to avoid over commitment and keep everyone efficient and organized.

Ready to propel the future of your company?